Texas City Explosion – Texas – April 16, 1947

Lack of awareness of the dangers from ammonium nitrate despite published guidelines and earlier similar

Lack of awareness of the dangers from ammonium nitrate despite published guidelines and earlier similar

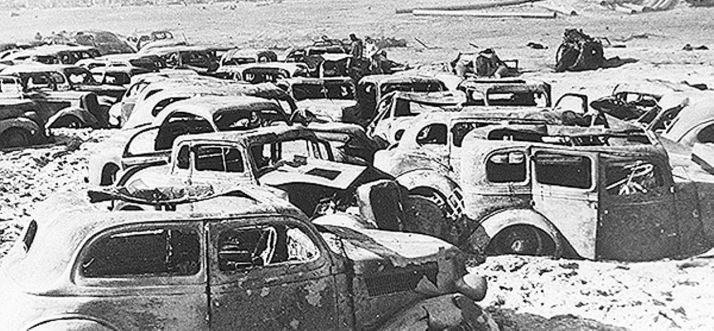

In the dying days of World War II inferior materials, because of war shortages, were

The explosion that ensued was one of the world’s greatest prior to the arrival of

Monongah was an exceptional example of the great risks that have always faced miners. While

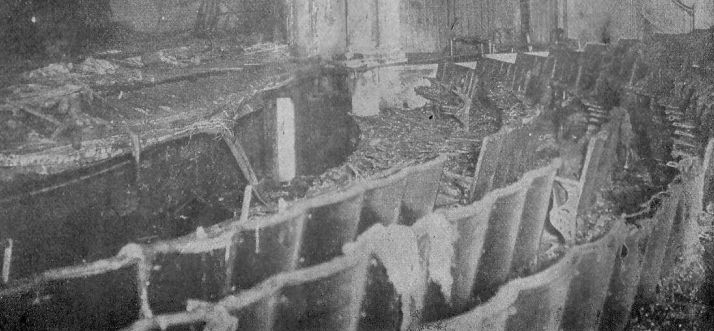

The theater that was claimed to be fireproof went up in flames shortly after its

A bigger fire, compared with all the previous ones, broke out in the center of

London was well acquainted with fires but the Great Fire was by far the worst

Most of Rome, the Capital of the Roman Empire, was destroyed by fire in 64

The city of Perm, lying on the European edge of the Ural Mountains 1,400 km

When in June 2009 fire spread from a warehouse to a center minding the children

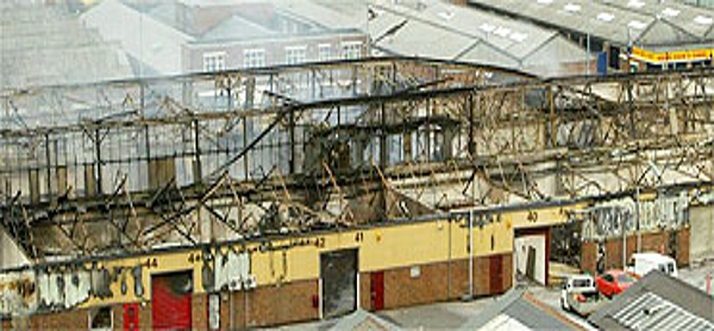

When in 2004 fire ripped through an East London warehouse housing a large selection of

There is a growing body of opinion in developed countries that people’s freedom is becoming

When it was announced that the 1980s rock act Great White would be headlining an

Nigeria is a country split by religion and factionalism. It is home to Christians and

One moment the neighborhood of Roombeek in the eastern Dutch city of Enschede was there,

The disco held in a Macedonian community center in Gothenburg was intended to provide some

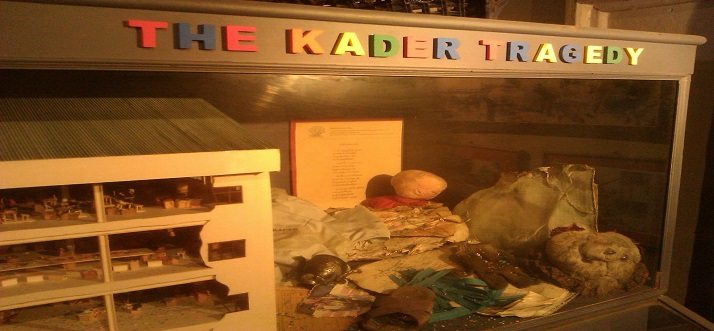

In 1993, Thailand’s worst-ever industrial disaster killed more than 180 workers in a catastrophic conflagration.

A major interchange on the London Underground system is King’s Cross St Pancras, a station

Do you think it’s ok to shoot the leaders of America? We all know what

How clean is the air you breathe? According to a new report, a mere seven

Can the crime rate be reduced in any of these cities? Living in cities with

Chicago is a destination known for its summer fun, sports, entertainment, food scene, diversity, and