Bad Reichenhall Ice Rink – 2006

Bad Reichenhall is a small town in the lovely Bavarian Alps, a popular winter sports

Bad Reichenhall is a small town in the lovely Bavarian Alps, a popular winter sports

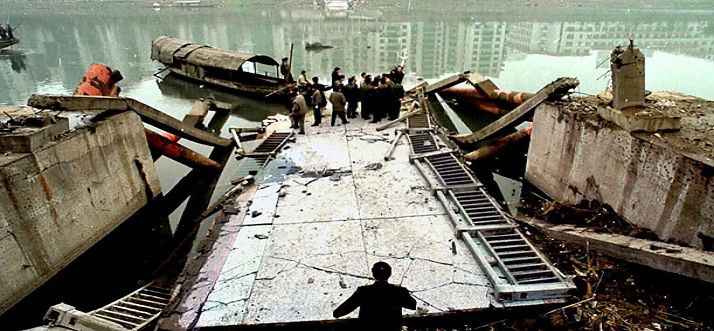

Entre-os-Rios is an attractive, prosperous town in lovely countryside north of the River Douro. By

South Korea’s construction boom in the 1980s and 1990s often meant corners were cut, rules

The township of Taman Hillview in Malaysia’s Klang Valley is conveniently close to Kuala Lumpur

The 1930s was a good time for infrastructure works in the USA, as that vast

As the name suggests, Ocean Ranger could indeed range. But in February 1982 this mobile

When the Hyatt Regency Hotel opened its doors for business in downtown Kansas City local

Having to deal with potentially hazardous substances in some of the fiercest weather the planet

The Teton Dam in the northwestern US state of Idaho enjoys a dubious reputation as

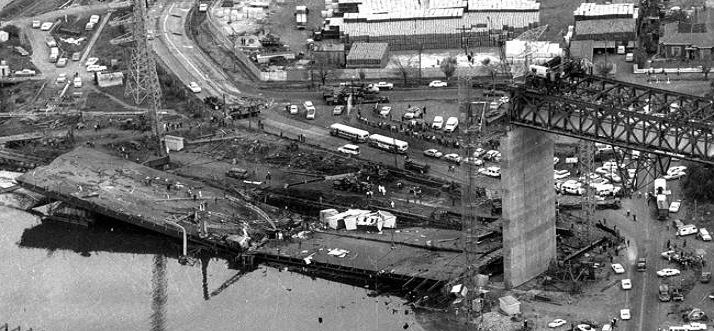

Melbourne’s West Gate Bridge across the Yarra River links the city to the suburbs and

Much of London’s East End was flattened by German bombs in World War II and

The postwar recovery of the Italian economy was driven by the great industrial cities of

The rocket launching site of Baikonur in Central Asia was at the heart of the

When the French government decided to build a dam to improve the water supply and

The first half of the last century witnessed a burgeoning enthusiasm for the suspension bridge,

One of the key issues affecting the development of Los Angeles was the provision of

Looking today at the imposing bulk of Quebec Bridge as it straddles the St Lawrence

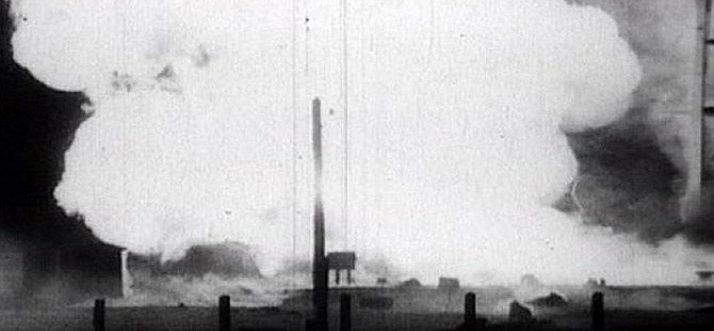

Detroit was on the cusp of its rebirth as Motor City and Henry Ford was

Do you think it’s ok to shoot the leaders of America? We all know what

How clean is the air you breathe? According to a new report, a mere seven

Can the crime rate be reduced in any of these cities? Living in cities with

Chicago is a destination known for its summer fun, sports, entertainment, food scene, diversity, and